Líderes del sector

Equipos de prueba de motores eléctricos

Las pruebas de motores eléctricos son esenciales para el éxito y la eficacia de su empresa. El equipo de prueba de motores eléctricos de ALL-TEST Pro proporciona análisis completos de la salud de los motores que van más allá de los métodos de prueba estándar para garantizar que sus motores sigan siendo fiables.

Mantenimiento predictivo de motores eléctricos.

Los tiempos de inactividad imprevistos pueden costar a los fabricantes hasta 22.000 dólares por minuto. No deje que la producción de su empresa se paralice y pierda tiempo y dinero valiosos.

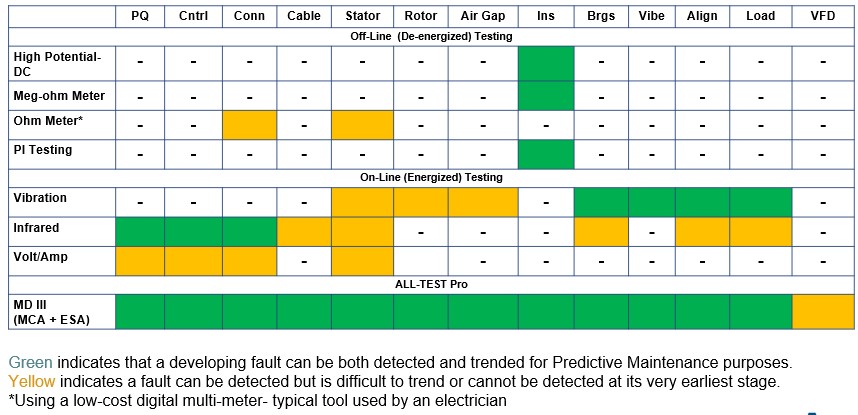

Nuestros avanzados dispositivos de análisis de motores alivian el estrés de los fallos imprevisibles de los motores para que su empresa siga funcionando. Nuestra línea de productos de mantenimiento predictivo de motores eléctricos (PdM ) llena los vacíos que otros productos de mantenimiento predictivo, como los monitores de vibraciones y los sensores de infrarrojos, no comprueban. Nuestros productos se aplican a todas las industrias que utilizan transformadores, motores eléctricos y generadores.

Gracias a nuestra larga reputación por nuestros excelentes productos y nuestro servicio de atención al cliente de primera categoría, nuestra empresa se enorgullece de contar con la confianza de importantes empresas de todo el mundo.

No hay otros instrumentos en el mercado que comprueben tantos factores con tanta precisión y rapidez como nuestros productos.

Las pruebas tradicionales con megóhmetros y multímetros no son suficientes

Las pruebas de aislamiento con megóhmetros sólo detectan fallos a tierra. Dado que sólo una parte de los fallos de los devanados eléctricos de los motores comienzan como fallos a tierra, no se detectarán utilizando únicamente este método. Además, las pruebas de sobretensión requieren la aplicación de altos voltajes que pueden ser destructivos al probar un motor, lo que lo convierte en un método inadecuado para la localización de averías y las verdaderas pruebas de mantenimiento predictivo.

Los dispositivos ALL-TEST Pro proporcionan un diagnóstico más completo de la salud de sus motores que cualquier otro dispositivo del mercado.

Issue | Meg-ohm Meter | Multi-Meter | ALL-TEST PRO 7 |

Ground Faults | |||

Internal Winding Faults | |||

Open Connection | |||

Rotor Faults | |||

Contamination |

Soluciones amplias y fiables

Pruebas sin tensión (MCA™)

El análisis de circuitos de motor (MCA™) permite realizar pruebas de motor sin tensión de toda la parte eléctrica del sistema del motor. Nuestros productos en esta categoría incluyen nuestros extremadamente populares ALL-TEST PRO 7™, ALL-TEST PRO 7™ PROFESSIONAL, ALL-TEST PRO 34™, ALL-TEST PRO 34 EV™ y MOTOR GENIE®.

Pruebas energizadas (ESA)

El análisis de firmas eléctricas (ESA) es un método de prueba energizado en el que se capturan formas de onda de tensión y corriente mientras el sistema del motor está en funcionamiento, para evaluar el estado del sistema del motor. En esta categoría, puede elegir nuestro ALL-TEST PRO On-Line III™ y nuestro ALL-SAFE PRO®, un accesorio del ATPOL III™.

Montajes

Nuestros conjuntos combinan ESA, MCA y software para mejorar la productividad de su planta con un rápido retorno de la inversión. Para un análisis completo del motor, ofrecemos el conjunto ALL-TEST PRO MD III™.

La opinión de los profesionales de la fiabilidad

Próxima formación

Comprobar motores eléctricos, ahora más fácil

Con una portabilidad, facilidad de uso y características de seguridad inigualables, la línea de equipos de comprobación de motores eléctricos ALL-TEST Pro permite a los técnicos evaluar los equipos sobre el terreno, en el taller o en una instalación de servicio.

¿Por qué probar los motores? Porque los motores fallan.

No todos los fallos de los devanados comienzan como fallos a tierra. Identificar los fallos del motor antes de que éste falle puede ahorrarle incontables horas de inactividad y gastos de mantenimiento.

Mantenimiento predictivo (PdM) y fiabilidad de motores eléctricos

All-TEST Pro es líder del sector en el desarrollo de equipos de pruebas preventivas de motores eléctricos y herramientas de mantenimiento predictivo (PdM). Nuestros dispositivos de comprobación de motores eléctricos utilizan tecnologías patentadas para analizar y diagnosticar problemas con el fin de garantizar la fiabilidad de los motores y reducir costes empresariales innecesarios.